Elon Musk, the name synonymous with innovation and disruption, is spearheading a tech revolution that is transforming industries as we know them. Through his revolutionary companies SpaceX and Tesla, he is driving change and pushing the boundaries of what is possible.

As an entrepreneur extraordinaire, Musk’s visionary approach is shaping the future of technology. Whether it’s revolutionizing space exploration with SpaceX or revolutionizing the automotive industry with Tesla’s electric vehicles, Musk is at the forefront of cutting-edge innovation.

With his relentless pursuit of innovation, Elon Musk is rewriting the rules of entrepreneurship. He challenges conventional thinking, takes risks, and pushes the limits of what is achievable. His commitment to creating a better future through technology has made him an inspiration to aspiring entrepreneurs worldwide.

Key Takeaways:

- Elon Musk is leading a tech revolution through his visionary companies, SpaceX and Tesla.

- His innovative approach is reshaping industries and pushing the boundaries of what is possible.

- Musk’s commitment to creating a better future through technology is inspiring aspiring entrepreneurs worldwide.

- SpaceX is revolutionizing space exploration, while Tesla is transforming the automotive industry with electric vehicles.

- Musk’s relentless pursuit of innovation and risk-taking sets him apart as a visionary entrepreneur.

The Role of AI and Machine Learning in Manufacturing

AI and machine learning technologies are revolutionizing the manufacturing sector, driving significant advancements and transformation. These innovative solutions are enabling manufacturers to streamline operations, improve efficiency, and enhance product quality.

Predictive Maintenance

One of the key applications of AI and machine learning in manufacturing is predictive maintenance. By leveraging data analytics and algorithms, manufacturing companies can proactively monitor equipment and predict potential failures before they occur. This approach minimizes unplanned downtime and reduces maintenance costs, ultimately maximizing production uptime and optimizing resource allocation.

Quality Control and Inspection

AI and machine learning algorithms are also being deployed in quality control processes to ensure higher accuracy and consistency in product manufacturing. These technologies can analyze vast amounts of data in real-time, identifying defects or anomalies that may be difficult for human inspectors to detect. With AI-driven quality control systems, manufacturers can maintain stringent quality standards, reducing the likelihood of product recalls and customer dissatisfaction.

“AI and machine learning technologies are revolutionizing the manufacturing sector, driving significant advancements and transformation.”

Optimized Production Planning

The implementation of AI and machine learning in manufacturing facilitates optimized production planning. These technologies can analyze historical data, industry trends, and market demand to generate accurate demand forecasts and supply chain recommendations. By leveraging this intelligent planning, manufacturers can avoid stock shortages, prevent excess inventory, and optimize production schedules, resulting in reduced costs and improved overall operational efficiency.

Process Optimization and Automation

AI and machine learning also play a vital role in process optimization and automation in manufacturing. By analyzing data from various sources, including sensor data, machine performance metrics, and environmental factors, these technologies can identify opportunities for improvement and automate repetitive tasks. This enables manufacturers to increase productivity, reduce waste, and allocate resources more effectively.

| Benefits of AI and Machine Learning in Manufacturing | Examples |

|---|---|

| Enhanced predictive maintenance | Reduced equipment downtime, increased reliability |

| Improved quality control | Higher accuracy, reduced defects |

| Optimized production planning | Effective resource allocation, minimized costs |

| Process optimization and automation | Increased productivity, reduced waste |

As the manufacturing industry continues to embrace AI and machine learning technologies, manufacturers can unlock new opportunities for growth, innovation, and operational excellence. By harnessing the power of these technologies, manufacturers can stay competitive and meet the evolving demands of the market.

With AI and machine learning driving advancements in predictive maintenance, quality control, optimized production planning, and process automation, manufacturers are poised to achieve new levels of operational efficiency and product excellence.

Robotics and Automation Reshaping Production Lines

Robotics and automation have become integral to the transformation of production lines in the manufacturing industry. The implementation of robotics and automation technologies has led to increased productivity and enhanced safety measures. With robots working alongside human operators, tasks such as assembly and handling hazardous materials are efficiently performed, reducing the risk of work-related accidents.

Automated assembly lines have revolutionized manufacturing processes, resulting in faster turnaround times and improved precision. By eliminating human errors and inconsistencies, automated systems ensure a higher level of accuracy in production. This not only leads to cost savings but also ensures product quality and customer satisfaction.

“The integration of robotics and automation has significantly transformed production lines. This advanced technology allows for seamless collaboration between humans and robots, enabling manufacturers to achieve new levels of efficiency, productivity, and safety.”

Benefits of Robotics and Automation in Production Lines

- Increased productivity: Robots can work at a faster pace, leading to higher production rates and reduced cycle times.

- Enhanced safety: By taking over hazardous tasks, robots minimize the risk of workplace accidents and injuries.

- Consistent quality: Automated systems ensure a high level of precision and accuracy in product assembly and manufacturing processes.

- Cost savings: By reducing human labor and minimizing errors, robotics and automation contribute to overall cost savings.

- Flexibility: Automated production lines can be easily reconfigured to accommodate different product specifications and variations.

Challenges in Implementing Robotics and Automation

While robotics and automation offer numerous benefits, their implementation also poses certain challenges. One of the key challenges is the initial investment required to adopt these technologies. The cost of acquiring and integrating robots into existing production lines can be significant, especially for small and medium-sized enterprises.

Another challenge is the need for specialized skills and expertise to operate and maintain the robotic systems. Training employees to work alongside robots and ensuring their seamless integration into existing workflows require time and resources. Additionally, concerns related to job displacement and workforce retraining need to be effectively addressed.

Impact of Robotics and Automation on the Workforce

The introduction of robotics and automation in production lines does bring changes to the workforce. While some jobs may be replaced or modified to accommodate automated systems, new roles and opportunities are also created. With robots taking over repetitive and hazardous tasks, human workers can focus on more complex and creative aspects of production.

| Impact on Workforce | Examples |

|---|---|

| Job displacement | Assembly line workers who previously performed repetitive tasks may need to transition to roles that involve programming and monitoring robotic systems. |

| New job opportunities | Specialized roles such as robot technicians and automation engineers are in demand to operate and maintain the robotic systems. |

| Collaborative work environment | Robots and humans working together result in a collaborative work environment, leveraging the unique strengths of each. |

Overall, the integration of robotics and automation technologies in production lines has proven to be a game-changer for the manufacturing industry. As technology continues to evolve, the benefits of robotics and automation are expected to expand further, driving advancements and revolutionizing the way products are made.

The Internet of Things (IoT) Driving Smart Manufacturing

The manufacturing industry is undergoing a transformative shift with the emergence of the Internet of Things (IoT). By connecting machinery and equipment to the internet, manufacturers can unlock a world of possibilities in optimizing production processes and enhancing overall performance.

Real-time monitoring is one of the key benefits of IoT in smart manufacturing. With sensors and devices interconnected, manufacturers gain the ability to monitor operations in real time, providing valuable insights into the efficiency of production lines and the status of equipment. This real-time data enables proactive decision-making, allowing manufacturers to identify and address issues before they escalate, reducing downtime and optimizing production.

Furthermore, IoT technology offers the opportunity for manufacturers to achieve optimized production processes. By collecting and analyzing data from various interconnected devices, manufacturers can identify bottlenecks, streamline workflows, and improve efficiency. This leads to increased productivity, reduced waste, and enhanced energy efficiency, contributing to a more sustainable and environmentally conscious approach to manufacturing.

One of the remarkable aspects of IoT in smart manufacturing is its ability to enable predictive maintenance. By continuously monitoring equipment performance and analyzing data, manufacturers can anticipate maintenance needs and plan accordingly. This not only minimizes downtime but also helps prevent unexpected breakdowns, extending the lifespan of equipment and reducing maintenance costs.

Benefits of IoT in Smart Manufacturing:

- Real-time monitoring of operations

- Optimized production processes

- Predictive maintenance

- Reduced downtime

- Improved productivity

- Enhanced energy efficiency

As smart manufacturing continues to gain momentum, the adoption of IoT technology becomes increasingly crucial for manufacturers looking to stay competitive in the market. By harnessing the power of IoT, manufacturers can drive innovation, improve operational efficiency, and embrace more sustainable practices, ultimately reaping the benefits of optimized production and improved performance.

With the Internet of Things revolutionizing the manufacturing industry, the possibilities are endless. By embracing IoT-driven smart manufacturing, manufacturers can unlock new levels of productivity, efficiency, and sustainability, setting the stage for continued innovation and success.

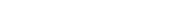

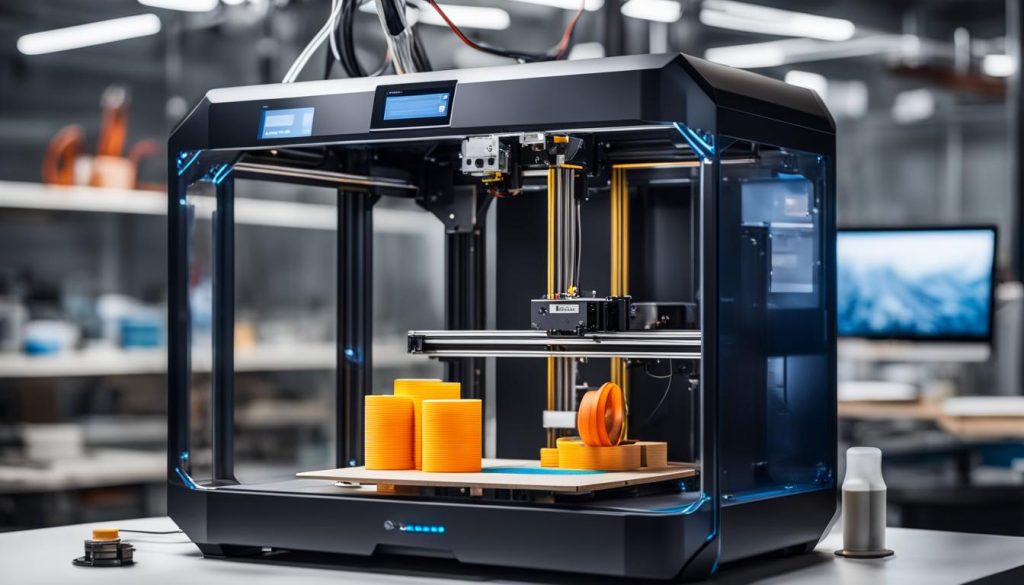

3D Printing’s Impact on Prototyping and Production

3D printing technology has revolutionized the way manufacturers approach prototyping and production processes. With its ability to quickly convert digital models into physical objects, 3D printing has accelerated the development timeline and unlocked new possibilities for rapid prototyping and iterative testing.

One of the key advantages of 3D printing is its capability to enable rapid development cycles. Traditionally, prototyping involved lengthy lead times and expensive tooling. With 3D printing, manufacturers can rapidly create physical prototypes, allowing for faster design iterations and reducing time to market.

Moreover, 3D printing offers customization options that were previously challenging to achieve. Manufacturers can easily adjust designs and produce small batches of specialized parts, catering to specific customer requirements. This not only expands market reach but also opens up opportunities for personalized and customized products.

Furthermore, 3D printing has simplified the production process by eliminating the need for complex assembly lines and expensive molds. This technology allows for the direct production of parts, reducing waste and optimizing resource utilization.

3D printing is particularly beneficial for industries that require intricate and complex designs, such as aerospace, automotive, and healthcare. It enables the creation of complex geometries and intricate structures that would be difficult or impossible to achieve through traditional manufacturing methods.

3D printing has revolutionized the prototyping and production landscape, empowering manufacturers to innovate faster, reduce costs, and cater to individual customer needs.

Benefits of 3D Printing in Prototyping and Production

Let’s explore the key benefits of 3D printing in prototyping and production:

- Accelerated development timeline: 3D printing enables rapid prototyping and iterative testing, reducing time to market.

- Cost-effective production: By eliminating the need for complex tooling and assembly lines, 3D printing streamlines the production process and reduces costs.

- Customization and personalization: Manufacturers can easily adjust designs and produce small batches of specialized parts, catering to individual customer needs.

- Design complexity: 3D printing allows for the creation of intricate designs and complex geometries, unlocking new possibilities for innovative products.

- Reduced waste: With direct production capabilities, 3D printing minimizes material waste, optimizing resource utilization.

Case Study: 3D Printing in the Automotive Industry

One industry that has embraced the benefits of 3D printing is the automotive sector. Automakers are leveraging this technology to improve efficiency, reduce costs, and enhance design capabilities. For example, companies like BMW and Audi have utilized 3D printing to produce lightweight and complex parts with optimized geometries, boosting the performance of their vehicles.

| Benefits of 3D Printing in Automotive | Examples |

|---|---|

| Reduced weight and improved fuel efficiency | BMW 3D printed aluminum brake calipers |

| Enhanced design possibilities | Audi 3D printed taillights with intricate designs |

| Faster prototyping and development cycles | Local Motors 3D printed an entire car in just 44 hours |

These examples highlight the potential of 3D printing in the automotive industry, where manufacturers can leverage this technology to achieve lightweight designs, unique aesthetics, and rapid prototyping.

In conclusion, 3D printing has had a transformative impact on the fields of prototyping and production. Its ability to accelerate development cycles, enable customization, and simplify production processes make it a valuable tool for manufacturers across industries. As this technology continues to advance, we can expect even greater innovations and applications that will shape the future of manufacturing.

Blockchain for Secure and Transparent Supply Chains

Blockchain technology is revolutionizing the world of supply chains in the manufacturing industry. With its decentralized and tamper-proof ledger of transactions, blockchain provides enhanced security and transparency, allowing stakeholders to build trust and ensure fraud prevention.

By leveraging the power of blockchain, manufacturers can create a secure and transparent supply chain ecosystem. Every transaction, from the procurement of raw materials to the delivery of finished products, is recorded and linked in a chain of blocks, providing an immutable and auditable history of events.

This transparency allows manufacturers to track and verify each step of the supply chain, ensuring the authenticity and quality of products. It also enables customers and regulatory bodies to access real-time information about the origin, handling, and distribution of goods, promoting a greater sense of trust and confidence in the overall supply chain process.

Furthermore, blockchain technology enhances supply chain security by reducing the likelihood of fraud and errors. With its decentralized nature, blockchain eliminates the need for intermediaries, such as third-party auditors, by providing a consensus-based mechanism for validating transactions. This reduces the risk of data manipulation and unauthorized access, increasing overall supply chain integrity.

In addition to secure supply chains, blockchain technology facilitates smoother logistics and operations. With a distributed ledger accessible to all authorized parties, manufacturers can streamline processes such as inventory management, shipment tracking, and payment settlements. This increased efficiency leads to reduced costs, faster turnaround times, and improved customer satisfaction.

Overall, blockchain technology brings a new level of transparency, security, and efficiency to manufacturing supply chains. By leveraging the power of decentralized transactions and consensus-based verification, blockchain ensures the authenticity and integrity of products while reducing the risk of fraud and errors. It is a transformative solution that is reshaping the future of supply chain management in the manufacturing industry.

Benefits of Blockchain in Supply Chains

| Benefits | Description |

|---|---|

| Enhanced Transparency | Blockchain provides a transparent and immutable record of transactions, allowing stakeholders to track and verify every step of the supply chain. |

| Increased Security | By eliminating the need for intermediaries and providing consensus-based verification, blockchain reduces the risk of fraud and unauthorized access. |

| Streamlined Operations | With a distributed ledger accessible to authorized parties, manufacturers can optimize inventory management, shipment tracking, and payment settlements, resulting in improved efficiency. |

| Trust and Confidence | Blockchain’s transparency and security features build trust among stakeholders, ensuring the authenticity and quality of products throughout the supply chain. |

Advancements in Human-Machine Interface (HMI) Technologies for Off-highway Automotive

The automotive industry is undergoing significant advancements in Human-Machine Interface (HMI) technologies for off-highway vehicles. These innovations are revolutionizing the user experience by offering intuitive interfaces, enhancing safety features, and enabling seamless interaction between drivers and their vehicles.

Gone are the days when operating heavy machinery required complex manual controls and extensive training. With HMI technologies, off-highway automotive vehicles now provide users with user-friendly interfaces that are easy to navigate, reducing the learning curve and improving overall productivity.

One notable advancement is the integration of touchscreens and gesture recognition systems in off-highway vehicles. These user-friendly interfaces allow operators to control various functions simply by touch or by making gestures, eliminating the need for physical buttons and switches. This intuitive interaction promotes efficiency and reduces the risk of operator errors.

Another remarkable innovation is the integration of voice recognition systems, enabling hands-free operation of off-highway vehicles. By simply speaking commands, operators can control various functions and access information without taking their hands off the steering wheel or controls. This promotes safety and reduces distractions, allowing operators to focus on the task at hand.

HMI technologies for off-highway automotive are not just limited to user interfaces. They also encompass advanced safety features that provide real-time feedback and alerts to operators. For example, proximity sensors and collision avoidance systems can detect obstacles and warn operators to take appropriate action, reducing the likelihood of accidents and enhancing overall safety.

Furthermore, HMI technologies enable seamless integration with other vehicle systems, such as GPS navigation and advanced diagnostics. Operators can access real-time information about their location, route planning, and vehicle health directly from the HMI interface, improving operational efficiency and reducing downtime.

The continuous advancements in HMI technologies for off-highway automotive vehicles are transforming the user experience and driving the industry towards safer, more efficient, and user-friendly machinery.

Democratizing Access to Advanced Semiconductors: A Blueprint for Empowering Small Businesses and Startups

Efforts are being made to democratize access to advanced semiconductors, empowering small businesses and startups. By providing affordable and accessible options, these initiatives aim to level the playing field and foster innovation in industries reliant on advanced semiconductor technologies.

“Democratizing access to advanced semiconductors is crucial for enabling small businesses and startups to thrive in today’s fast-paced technological landscape. These companies often face barriers to entry due to the high costs and limited availability of advanced semiconductor chips. However, by making these technologies more accessible, we can unlock their potential to drive innovation and fuel economic growth,” says Dr. Sarah Johnson, CEO of TechBoost, a leading semiconductor manufacturer.

Advanced semiconductors play a vital role in various industries, from consumer electronics and automotive to healthcare and renewable energy. These chips, which are at the heart of modern technologies, enable faster processing speeds, increased storage capacity, and enhanced performance. However, the high costs and complex manufacturing processes associated with advanced semiconductor production have traditionally limited their availability to larger corporations with substantial financial resources.

To address this challenge, industry leaders, governments, and research institutions are working together to democratize access to advanced semiconductors. They are investing in research and development to reduce manufacturing costs, exploring new materials and fabrication techniques, and promoting collaborations to share knowledge and resources.

Initiatives Driving Access to Advanced Semiconductors

One such initiative is the Small Business Semiconductor Program (SBSP), a collaborative effort between industry giants and government agencies. The SBSP aims to provide small businesses and startups with affordable access to cutting-edge semiconductor technologies, allowing them to develop innovative products without the financial barriers that often restrict their growth. Through the program, participants receive support in the form of reduced fabrication costs, mentorship, and access to state-of-the-art semiconductor manufacturing facilities.

Furthermore, open-source platforms and community-driven initiatives are emerging to democratize access to advanced semiconductors. These platforms provide free access to design files, fabrication processes, and testing methodologies, enabling small businesses and startups to develop their own chips or customize existing ones based on their specific needs. This collaborative approach fosters innovation, accelerates product development cycles, and encourages knowledge-sharing among diverse industry players.

The Impact on Small Businesses and Startups

The democratization of access to advanced semiconductors empowers small businesses and startups by leveling the playing field and providing them with the tools to compete with larger corporations. By harnessing the power of semiconductor technologies, these companies can develop cutting-edge products, enhance competitiveness, and drive growth in their respective industries.

For example, in the healthcare sector, small businesses and startups can leverage advanced semiconductor technologies to develop portable medical devices, remote monitoring systems, and personalized healthcare solutions. These innovations have the potential to revolutionize patient care, improve health outcomes, and reduce healthcare costs.

In the renewable energy industry, startups can utilize advanced semiconductors to optimize solar panels, improve energy storage technologies, and enhance energy management systems. These advancements contribute to the transition to a more sustainable future by increasing the efficiency and reliability of renewable energy sources.

By democratizing access to advanced semiconductors, small businesses and startups can unleash their creative potential, disrupt industries, and bring novel solutions to market. This fosters a culture of innovation, propelling economic growth, and creating opportunities for job creation and technological advancement.

The Future of Advanced Semiconductors

The democratization of access to advanced semiconductors is an ongoing journey, driven by the collective efforts of industry stakeholders, governments, and research institutions. As advancements in semiconductor technologies continue to unfold, the scope of possibilities for small businesses and startups will expand even further.

With greater accessibility to advanced semiconductors, small businesses and startups can drive technological advancements, fuel economic growth, and contribute to the development of a more inclusive and innovative society.

| Key Benefits of Democratizing Access to Advanced Semiconductors |

|---|

| 1. Leveling the playing field for small businesses and startups |

| 2. Encouraging innovation and creativity |

| 3. Driving economic growth and job creation |

| 4. Revolutionizing industries with advanced semiconductor applications |

| 5. Fostering sustainability and energy efficiency |

Conclusion

Elon Musk, the entrepreneurial genius behind SpaceX and Tesla, is at the forefront of innovation and is transforming industries such as electric vehicles and space exploration. With his visionary mindset and unwavering determination to break boundaries, Musk has solidified his position as a prominent figure in the tech industry, revolutionizing the way we think about technology, innovation, and the future.

Through SpaceX, Musk has propelled the boundaries of space exploration by successfully launching reusable rockets and paving the way for a more accessible and sustainable approach to space travel. His ambitious goals of colonizing Mars and making humanity an interplanetary species have sparked a new wave of excitement and possibilities in the field of space exploration.

Similarly, with Tesla, Musk has disrupted the automotive industry by introducing electric vehicles that are stylish, high-performing, and environmentally friendly. His relentless pursuit of sustainable transportation has not only pushed the boundaries of innovation but also accelerated the shift towards a greener future.

As technology continues to evolve at an unprecedented pace, Elon Musk’s influence and impact are expected to grow even further. His commitment to pushing boundaries, his unwavering belief in the power of innovation, and his ability to create cutting-edge technology have solidified his position as a billionaire entrepreneur who is shaping the future of multiple sectors. Elon Musk’s ventures are a testament to the transformative power of technology and the limitless possibilities that lie ahead.